Introduction

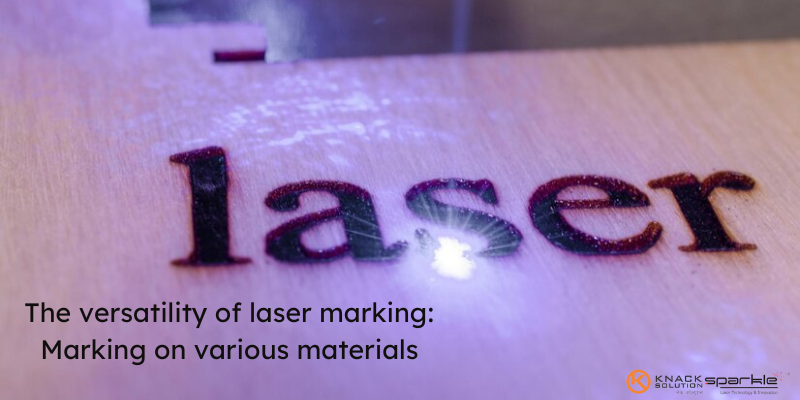

Laser marking is a versatile technology that can be used to mark a wide variety of materials. From metal to plastic, and from glass to ceramics, laser marking machines can produce high-quality and permanent marks on many different surfaces.

There are several different types of laser marking machines available, each of which is designed to work with specific materials and applications.

Types of Laser Marking Machines

Sparkle Laser: Marking on Metal Surfaces

One popular type of laser marking machine is the Sparkle Laser. This type of laser uses a high-powered laser beam to produce bright, high-contrast marks on metal surfaces.

The sparkle laser is particularly well-suited for marking on stainless steel, aluminium, and other metal surfaces, and it can be used to produce a wide range of different mark types, including text, logos, and barcodes.

Industrial Laser Machine: Marking in Industrial Settings

Another type of laser marking machine is the industrial laser machine. This type of machine is designed for use in industrial settings and is typically used to mark large quantities of parts or products.

Industrial laser machines are often used in manufacturing plants, where they are used to mark parts or products with serial numbers, barcodes, or other identifying information. They can also be used to mark products with expiration dates, warnings, or other important information.

CO2 and Fiber Laser: Marking on Non-metal Materials

Laser Marking Machines can also be used to mark a wide variety of non-metal materials, including plastic, glass, and ceramics. These machines use a different type of laser than the sparkle laser, such as CO2 or Fiber laser, which are more suitable for marking on non-metal materials.

These types of lasers can be used to produce high-quality, permanent marks on a wide variety of different materials, including plastic, glass, and ceramics. They can also be used to produce a wide range of different mark types, including text, logos, and barcodes.

Advantages of Laser Marking:

- High-Quality and Permanent Marks: One of the main advantages of laser marking is that it produces high-quality and permanent marks on a wide variety of materials. The marks produced by laser marking are clean, precise, and highly detailed, and they are also resistant to fading or wearing away over time.

- Wide Range of Mark Types: Another advantage of laser marking is that it can produce a wide range of different mark types, including text, logos, barcodes, and other types of graphics. This makes it an ideal technology for a variety of different applications, from product identification to decorative markings.

- Suitable for Large Quantities of Parts or Products: Laser marking machines are able to handle large quantities of parts or products, making it ideal for mass production.

Applications of Laser Marking:

- Marking Metal Parts in Industrial Settings: Laser marking machines are widely used in industrial settings to mark metal parts with serial numbers, barcodes, or other identifying information. They are also used to mark products with expiration dates, warnings, or other important information.

- Marking Plastic Products with Specific Messages: Laser marking machines can also be used to mark plastic products with specific messages, such as product information, instructions, or warnings.

- Marking Glass and Ceramic Materials: Laser marking machines can also be used to mark glass and ceramic materials, such as glass bottles, ceramic tiles, and other similar products. This can include product identification, company logos, or other types of graphics.

- Other applications includes: Medical device marking, aerospace and automotive industry, Jewellery marking, Food and beverage industry, Electronics marking and many more.

Conclusion:

In conclusion, laser marking is a versatile technology that can be used to mark a wide variety of materials with high-quality and permanent marks. It has several advantages such as high-quality, permanent marks, wide range of mark types and it is suitable for large quantities of parts or products.

The applications of laser marking are diverse, including marking metal parts in industrial settings, marking plastic products with specific messages, and marking glass and ceramic materials.