The Fiber Stamping Machine can be used to stamp on metal or plastic surfaces for clear, permanent, and precise markings. The printer utilizes the most current use of fiber optics technology and an easy-to-use access point for users, allowing repeatability and durability in today’s production plants.

Stamping Machine allows industries to meet the demand for required quality, speed, and dependability. It is widely used due to its ability to produce high-quality marks with low power consumption and little to no maintenance. The machine is suitable for stamping everything from serial numbers and logos to highly detailed graphics and barcodes, offering manufacturers exceptional flexibility within the engraving market.

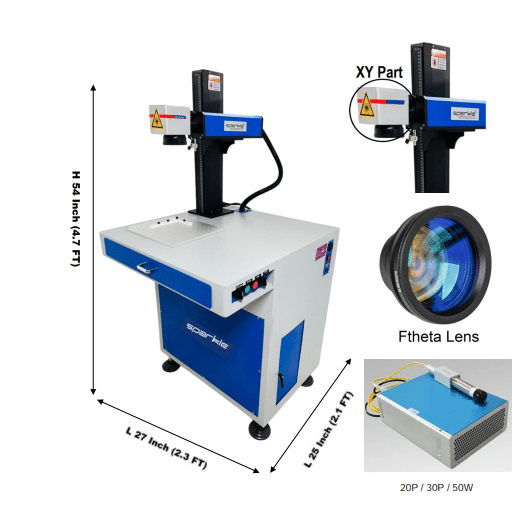

The overall design of the Fiber Stamping Machine is compact and portable, allowing it to be easily incorporated into existing production lines. This design does not sacrifice quality at any stage of the process, supported by smart software integration and reliable performance.

Advanced Stamping Technology for All Materials

The Fiber Stamping Machine can be used on a wide range of materials including aluminium, stainless steel, brass, titanium, plastic, alloy steel, bronze, copper, platinum, and more.

The machine uses a tool-type stamping method with adjustable power settings. It creates clear, precise, and permanent impressions at controlled depths while maintaining excellent consistency. Equipped with a cool air system and stable power delivery, the machine is suitable for continuous industrial production.

Key Features of Fiber Stamping Machine

Some of the key features of the Fiber Stamping Machine include:

- Portable & Compact Design: Easy to move and install, offering versatility when setting up production environments.

- High Precision & Accuracy: Enables micro-stamping with a minimum character height of 0.2 mm.

- Wide Power Range Options: Available in 20W with optional 30W, 50W, 80W, and 100W configurations for various marking requirements.

- Real-Time Red Beam Preview: Allows accurate placement of marks before stamping.

- Circumferential & Round Part Stamping: Suitable for cylindrical and rounded components.

- Auto Stamping with Boundary & Round Preview: Improves efficiency, repeatability, and minimizes errors.

- Easy Stamping on Complex Designs: Supports logos, serial and part numbers, alphanumeric characters, barcodes, 2D matrix codes, and graphics.

- Multiple File Format Support: PLT, SVG, DXF, DWG, BMP, JPEG, and PNG formats are supported.

- Low Power Consumption & Maintenance Free: Operates at approximately 500 watts, helping reduce operational costs.

Applications of Fiber Stamping Machine

Fiber Stamping Machines are widely used across various industries due to their precision and reliability.

- Automotive Components: Used for permanent marking of engine parts, components, and accessories that can withstand heat, friction, and harsh conditions.

- Industrial Manufacturing: Ideal for marking tools, machine parts, and heavy components with consistent precision for traceability and quality control.

- Electrical & Electronic Components: Suitable for stamping electrical panels, switches, connectors, and housings without damaging delicate components.

- Metal Fabrication: Used for stamping sheets, pipes, plates, and fabricated structures for identification and branding.

- Tool & Die Marking: Provides clear, permanent markings on dies, moulds, and cutting tools for inventory and usage tracking.

- Plastic Parts Identification: Enables controlled-depth stamping on plastic parts without cracking or surface distortion.

- Jewellery & Decorative Items: Used for engraving fine details, logos, serial numbers, and artistic designs with high precision.

Why Use Sparkle Laser’s Fiber Stamping Machine?

- High-Speed, Accurate & Permanent Marking: Delivers fast stamping without compromising image quality.

- Works on Metals and Plastics: Suitable for a wide variety of industrial applications.

- Compact & Portable: Easy installation and mobility across workstations and automated production lines.

- Low Operating Costs & Maintenance Free: Energy-efficient design ensures long-term dependability.

- Compatibility with Modern Automated Industries: Supports current software, automation systems, and Industry 4.0 integration.