Inflation and uncertainty in the economy are not the only themes playing out in our manufacturing world. Precision, strength, and efficiency are more important today than ever. Industries are searching for ways to achieve not just metal joining, but tougher, longer lasting bonds. For automotive and aerospace components, medical devices, and energy systems, the ideal, high-performance laser welding machine has been more in demand.

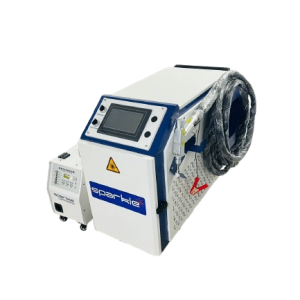

Sparkle’s 6-Axis Fiber Laser Welding Machine leverages fiber laser technology to achieve precision welding through a fully programmable 6-axis motion platform for better flexibility, efficiency, and unrivaled welding capability.

With power ranges from 500W to 3000W, Sparkle’s 6-Axis Laser Welding Machine is designed to provide the right accuracy and strength for any application, including microwave sizes welds, through to deep, multi-pass welding of thickness materials.

The motion system used in the 6-Axis Laser Welding Machine helps to limit heat distortion, minimize rework, and deliver consistent strength and clean welds. Let’s explore in detail!

How the 6-Axis Fiber Laser Welding Machine Works?

At the heart of the machine, is a high-powered fiber laser beam with a wavelength of 1064 nm, the ideal wavelength for metal applications since it has a very high absorption in metals. You can choose between pulsed or continuous wave operation with various pulsed modulation frequencies anywhere from 1 Hz to 20 kHz, giving you control over both the penetration depth and weld quality.

The automatic fiber laser-welding head, with precision water-cooling, directs the beam through its specialized servo motors with complete accuracy. And, if the application does require filler material, there is an optional wire feeder of 0.8 mm to 1.6 mm for consistent deposition.

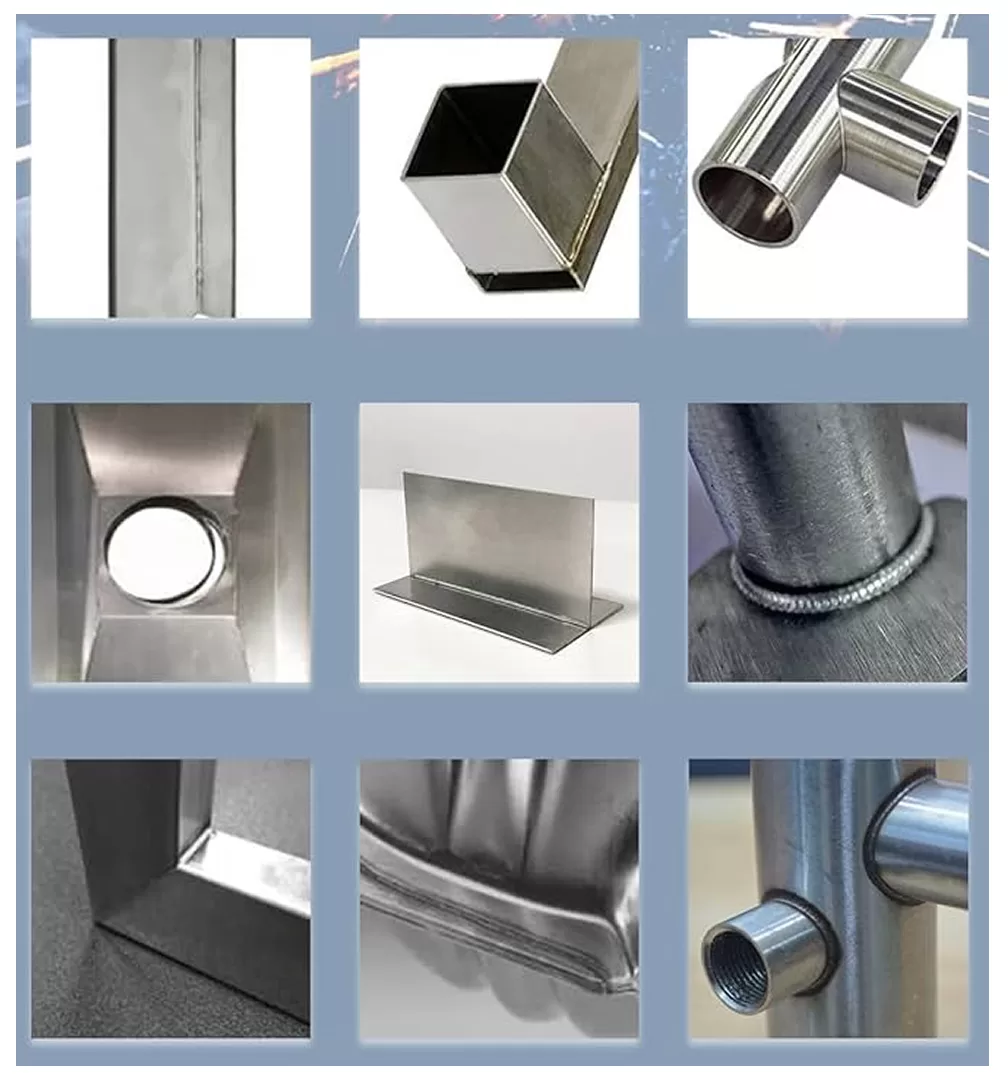

This machine also has a 6-axis CNC motion system and along with trade-offs in motion range between X-axis for 600 mm, Y-axis for 400 mm, Z-axis for 300 mm and full ±360° rotation capabilities across the A, B and C axis, this machine can weld the most complex 3D geometries and curved surface. With a high precision servo motor with ball screw and linear guide movement system, the 6-axis machine provides an incredible ±0.02 mm repeat positioning accuracy, making it ideal for both one-off parts and mass production!

With linear speeds of up to 30 m/min attached with CAD/CAM supported welding path programming, this system is fast enough for production line operations and custom work. The real-time monitoring and adjustable process parameters also gives you a piece of mind that each weld is produced with accuracy and reliability!

Top Features of the 6-Axis Fiber Laser Welding Machine

Multiple Power Options

Select laser power configurations from 500W to 3000W laser power to suit your exact production needs. Whether it’s delicate thin sheets or welding thicker metals, there is a power level for your application.

Unmatched Precision

With beam quality and repeat accuracy of ±0.02 mm, every weld is clean, sharp, and consistent which results in little to no spatter, strong joints and less post-processing work.

6-Axis Motion System

The sophisticated 6-axis motion plan provides the ultimate freedom for 3D welding, curves, angles or irregular parts will be handled as easily as the straightest run to enhance your applications flexibility.

Advanced Control System

The industry leading CNC control system with touchscreen provides a friendly user interface. Quick programming of CNC made simple with CAD/CAM import for complex paths and multi-axis interpolation.

Multiple Welding Modes

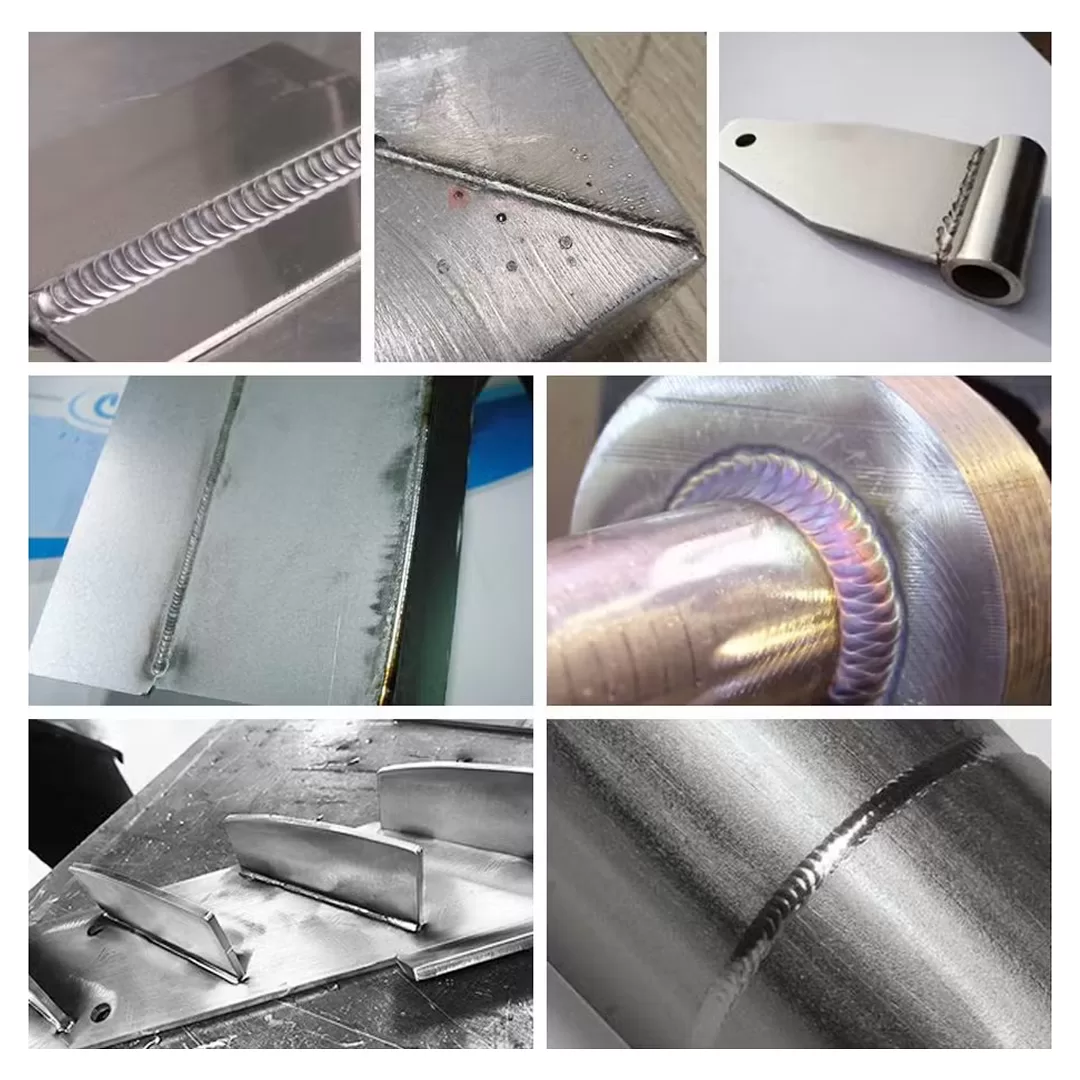

From spot and seam weld to overlap or multi-layer welds, this machine is capable of completing a variety of jobs. You can utilize it for everything from micro-welds to deep penetration joints.

Industrial Grade Cooling

Our efficient water chiller maintains a temperature range between 5°C to 35°C. Maintains constant operating conditions and consistent weld quality even on long production shifts.

Safety

Optional laser safety glass, interlocks, fume extraction and emergency stop features ensure your operators are safe while remaining productive.

Robustness and Longevity

With a fiber laser source that is designed to last for years, the system incurs very little maintenance costs. You are ensured the reliability of consistently having the system available for use, more operational use time equals less total accrued costs of operation.

Applications of the 6-Axis Laser Welding Machine

Automotive

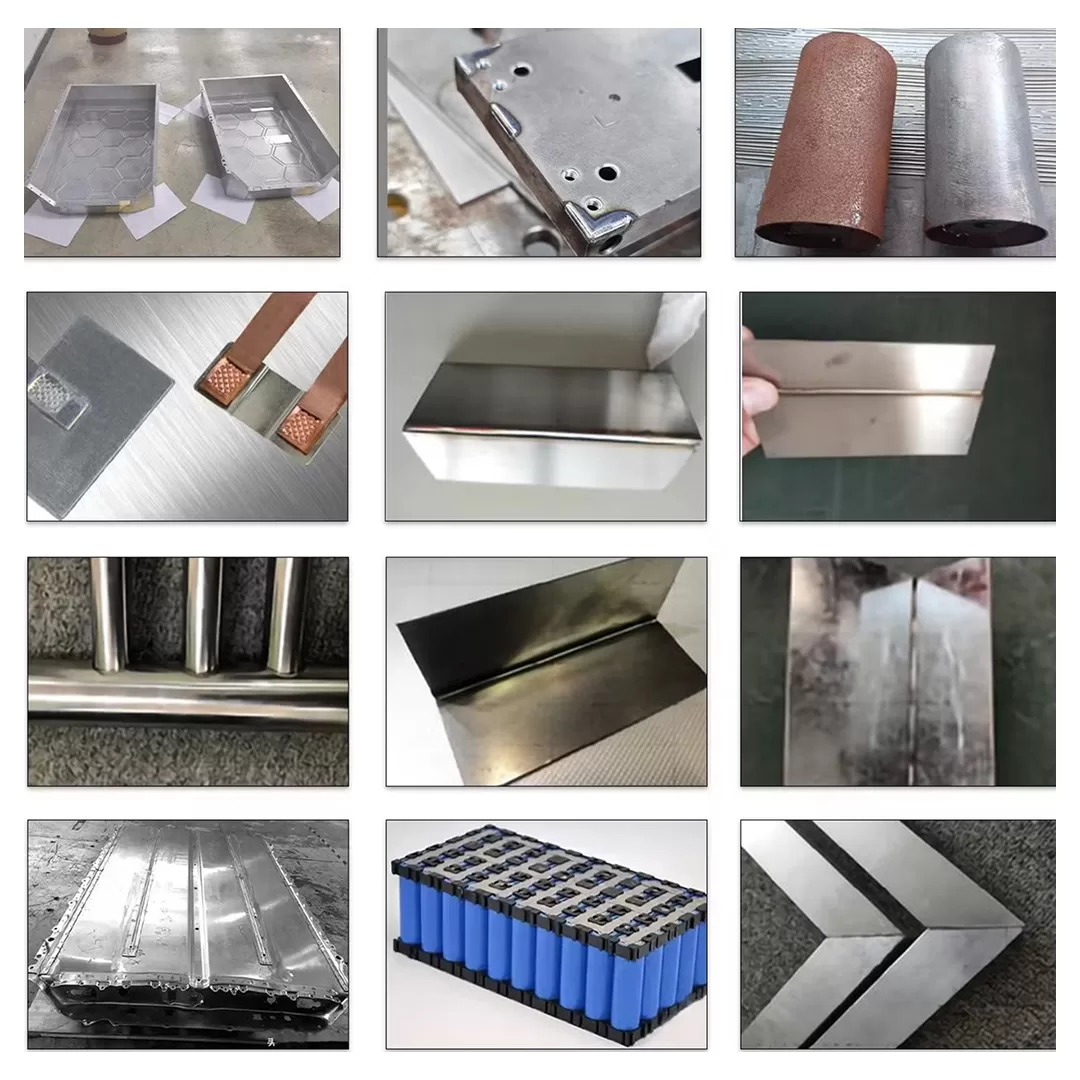

From gear boxes and exhaust systems to sensors and battery tabs, the role of the laser welding machine in today’s automobile manufacturing process is paramount. Its alignment of high precision with near-zero heat distortion makes it the ideal machine for consistent joint making in safety-critical automotive parts while ensuring high-speed and productive delivery.

Aerospace

Aerospace engineering has no tolerance for error. The 6-axis laser welding machine is perfect for welding titanium structures, engine components, and lightweight frame assemblies, reducing the heat effect from welding whilst creating clean and trustworthy joints. The machine’s capacity to work from different angles also allows for the welding of complex, yet curved aerospace components to a flawless finish.

Electronics

In electronics, precision is everything, and the 6-axis laser welding machine is the most proficient means of microwelding connectors, housings, and enclosures. This machine guarantees strong and dependable connections on very small components without damaging other parts, making it a compulsory instrument for advanced and high-tech electronics manufacturing.

Medical Devices

In medical device manufacturing, there is zero tolerance for inaccuracies or non-cleanliness. The 6-axis fiber laser welding is perfect for welding surgical instruments, stainless implants, and small and complex components in a way that allows for biocompatibility and durability within life-saving medical devices.

Energy Storage

Due to the rise in demand for electric vehicles and renewable energy, the 6-axis laser welding machine is vanishingly important to welding EV battery packs and energy storage systems. The machines providing really precise welding will generate trusted joinery.

Benefits of Using Sparkle’s 6-Axis Fiber Laser Welding Machine

Precision and Quality

Every weld produced is clean, strong, and dependable. There is nearly 100% reduction of distortion and spatter from welding; so you receive a good finish right out of the machine which avoids the potential of work being reworked.

3D Flexibility

The system has six axes in a flexible welding format that can weld in any angle and position, even on curved or irregular geometric surfaces. This grants freedom to make more complicated geometry and designers can take advantage of modern technologies/added designs that can influence the welding process.

Speed and Efficiency

The welding speed can be up to1260 inches (30 meters) a minute with numbers as high as 39000 inches a minute. The system integrates pre-programmed procedures that are consistent at the same time with repeatability from batch to batch!

Material Flexibility

There is capacity and durability to utilize materials in stainless steel, carbon steel as well as materials as aluminum, copper, titanium, and nickel alloys, and all base materials are produced and held with the system accurately.