How AI and IoT Are Transforming the Laser Machine Industry

Artificial intelligence and IoT are set to radically influence how the laser machine industry works. From the high-volume industrial laser machines used for marking and engraving to exquisitely specialized laser soldering machines used for jewellery, all new AI-and-IoT-driven innovations have begun to change the behaviour and thinking behind these types of machines into a new normal with greater efficiency, precision, and scalability.

The Evolution of Laser Machines

Laser machines were originally respected for their capabilities in performing high-precision operations such as cutting, engraving, and marking on various materials. Beginning with Sparkle Laser Technology, several companies have been pioneering this evolution, inventing cutting-edge solutions for industrial and jewellery sectors, among others. However, with the infusion of AI and IoT, this drive is set to continue as the industry looks to better itself immensely beyond traditional capabilities, delivering smarter, quicker, and highly efficient machines.

AI’s Role in Laser Machines

Precision and Optimization

AI allows the laser machine to have incredible accuracy. Machine learning algorithms analyze historical data to automatically set power, speed, and focus. This guarantees high-quality results for all processes. The AI-induced laser marking machines, for example, are capable of switching between different material types-from metals to plastics-without the need for any manual adjustments.

Predictive Maintenance

AI allows for the very insightful prediction of maintenance. Algorithms can analyze real-time performance data, alert potential failures, and advise on possible maintenance scheduling before a problem occurs. That alone cuts down on times of inactivity, repairs, and flowing the increased productivity; hence very valuable for the industrial manufacturers.

Enhanced User Experience

Machine operation has been made simpler through AI-driven interfaces, allowing even non-technical personnel an easy time with using the machines. Through well-structured dashboards, the operator can easily monitor performance metrics, troubleshoot issues, and receive training recommendations to work more efficiently.

IoT in Laser Machines

Real-Time Monitoring and Control

The Internet of Things provides connectivity to laser machines, enabling real-time monitoring and control from remote locations. This capability is especially beneficial for industries relying on continuous operations, thereby assuring that machines remain strictly operational in optimum conditions.

Data-Driven Insights

Such laser machines have the potential to produce vast amounts of information, which can then be leveraged to derive useful insights. Take for example the case of IoT sensors embedded within laser soldering machines, which can assist jewelry makers in identifying patterns leading to quality soldering while minimizing waste.

Integration with Smart Factories

IoT connects laser machines to a larger smart factory ecosystem. In that regard, it enables seamless communication between multiple machines; thus, workflow is optimized within such systems to allow manufacturers the capability to scale operations more efficiently.

Applications in the Industrial Sector

Laser Marking for Product Identification

Industrial laser marking machines equipped with IoT and AI redefine the product identification processes. Such machines engrave serial numbers, barcodes, and logos with unmatched perfection to meet compliance with regulatory standards.

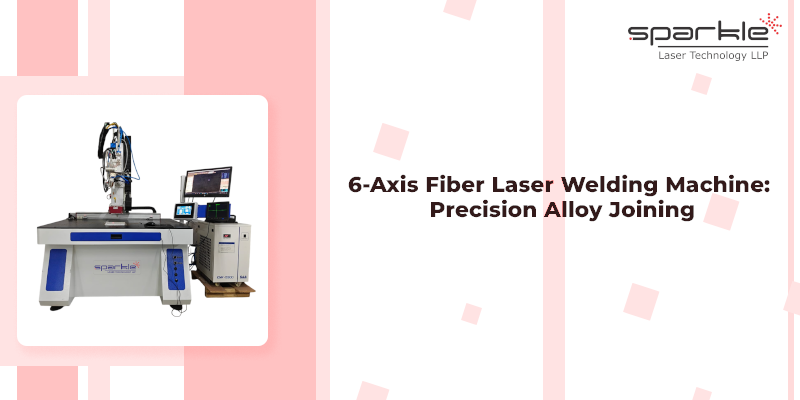

Engraving and Cutting

Visualise industrial laser machines capable of performing complex engraving or cutting tasks, from the simplest ones to those meeting aerospace and automotive sector demands. With the IoT connectivity, its performance can go a notch higher with remote operation and monitoring.

Applications in the Jewelry Industry

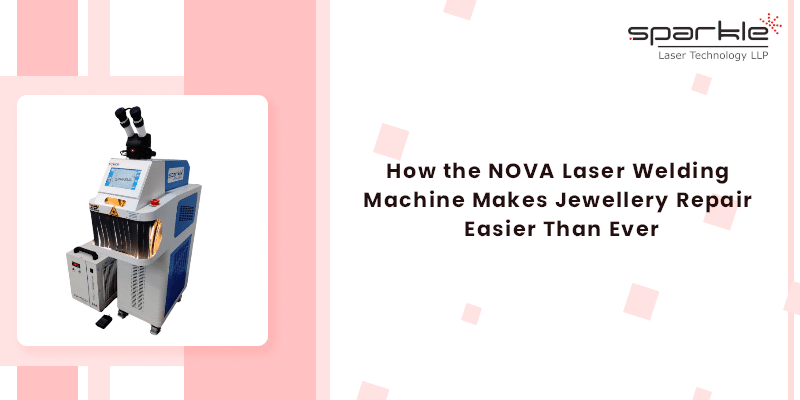

Precision Soldering

If jewellery making was drawing the line at incredible accuracy, AI and IoT-enabled laser soldering machines deliver. They reduce errors and wastage during soldering, ensuring designs with an intricate and elaborate setup. The AI algorithms optimize the laser soldering parameters based on design complexity while IoT assures quality monitoring in real time.

Customization and Personalization

The customized jewellery landscape is rapidly changing with AI-based laser engraving machines. From engravings to detailed ornamental designs, these machines make it simpler for jewellers to create entirely custom pieces. Moreover, IoT’s capability of remotely monitoring and controlling these machines gives added convenience.

Benefits of AI and IoT in Laser Machines

Increased Efficiency

By automating complicated processes and optimizing the operational parameters, AI and IoT drive machine efficiency. This means faster production cycles and higher throughput.

Cost Savings

Predictive maintenance and real-time monitoring mean lower operational costs by reducing downtime losses and avoiding expensive repairs. Besides, the precision of AI-driven machines translates into lowered material waste and more savings.

Improved Product Quality

AI ensures uniformity of operations, thus delivering outputs of higher quality. This assures consistency and is of enormous help to industries, such as jewellery to produce, where there is a requirement for precision.

Scalability

IoT connectivity means that manufacturers can scale up their operations without too much fuss. Machines can be part of much larger networks, creating integrated systems that can be managed, augmented, and expanded quite easily.

Challenges and Solutions

Data Security

Along with connectivity comes vulnerability exploitation by cyber threats. To tackle this, manufacturers are investing in robust cybersecurity like encrypted communications and secure authentication protocols.

High Initial Costs

Although integration of AI and IoT is costly, its return on investment in efficiency and cost savings exceeds the initial investment. Sparkle Laser Technology is exemplary for being possibly the first to provide affordable solutions appropriate for all budgets.

The Future of Laser Machines

The combo of AI and IoT is only the beginning. Future innovations may involve the introduction of augmented reality (AR) for more productive user training, advancing the required number of simulations, applying blockchain for data management and secure transactions, and even incorporating advanced robotics that would automate all workflows. As technology continues to develop, so too will new innovations in laser machines.

Conclusion

AI and IoT are already transforming the laser machine industry’s smart and efficient ecosystem utilized in industrial applications such as marking and engraving or for specialized functions within jewellery manufacture-all aimed to provide manufacturers with enhanced precision, efficiency, and scalability. Sparkle Laser Technology is an example of this rising trend in the application of AI and IoT to provide innovative solutions for meeting their customers’ diverse needs.